The VIGILEX VQ is a new explosion protection device that protects equipment inside your facilities.

It guarantees total protection against flames and dust in the event of an explosion. Burnt dust does not pass through the VIGILEX VQ, and high explosion temperatures are reduced to a minimum. In a conventional explosion, where the explosion is released with the help of vents, flames and dust are always projected outside the enclosure, with possible consequences for the surrounding environment.

When the process is located inside a building, the equipment (filter, hopper, silo, bucket elevator, etc.) is generally protected by a discharge "duct" which carries the explosion to the outside of the building. However, this type of discharge pipe is a very expensive solution, difficult to install and greatly reduces the coefficient of efficiency.

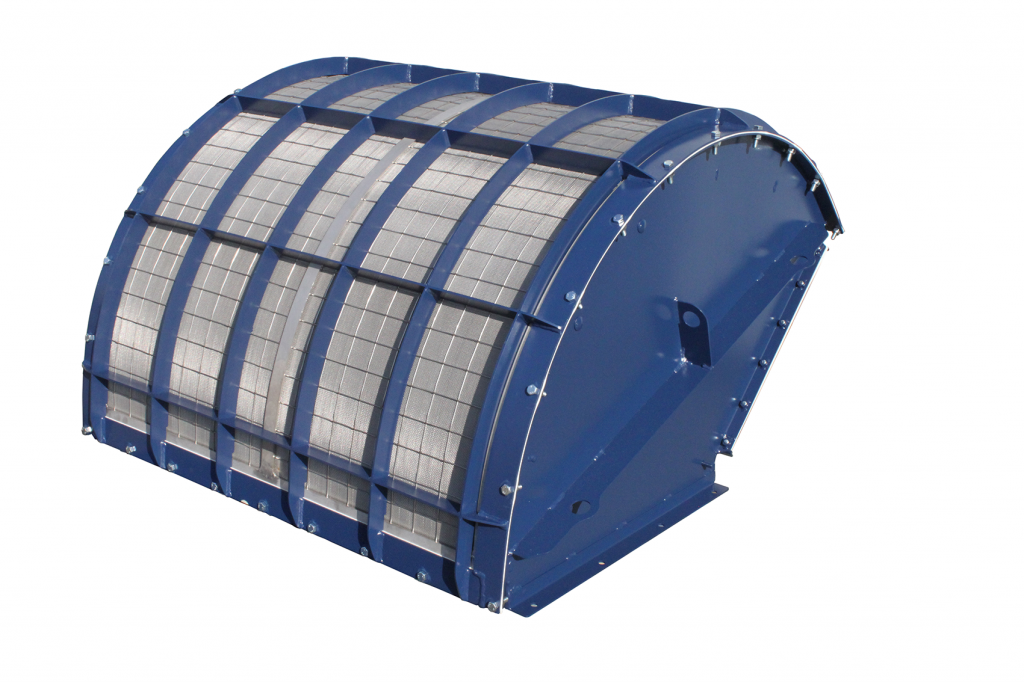

In contrast, our VIGILEX VQ Flame Arrestor; ATEX-certified to the latest EN16009:2011 standard (Standard on flameless explosion discharge devices) with INERIS (CE Certificate: INERIS 14ATEX0049X) is the ideal device for protecting both indoor and outdoor equipment. In the event of an explosion, it extinguishes flames and stops high-temperature emissions. A minimal safety distance in front of the VQ is required, leaving more space for production. The VIGILEX VQ is rectangular in shape and includes a standard explosion vent and a rupture detector. A rear door allows the vent to be installed on initial assembly, or changed if necessary.

The VQ flame arrestor is available in a range of sizes, with an optional filter protection bag (VIGILEX COVER). The VIGILEX VQ boasts some of the best technical features on the market, including: KST Max 350, Pred 2 bar, Pmax 10 bar. STIF is the first French company to be ATEX-certified to EN16009:2011 for flame arresters, and the only European company to have this certification for Rectangular flame arresters. STIF is also ISO9001 AFAQ certified by AFNOR.